Tackling Global Poverty One Note at a Time

George Korir ’06 creates a clever and useful chemistry kit for under-resourced communities.

WHEN DOES A MUSIC BOX BECOME A PRACTICAL, economical, poverty-fighting tool? When you put it into the hands of scientists for whom poverty is personal.

The fifth of eight children, George Korir ’06 spent most of his formative years in Roret, a small village outside the city of Nakuru, Kenya. His father, a veterinarian, and mother, a nurse, grew crops to earn income so they could send their children to the best schools. Korir remembers Roret as an exciting place to grow up. “We often played with our neighbors, grew most of the food we ate and felt happy and safe.”

He also remembers some of the harsh realities, particularly access to water. Families relied on untreated rainwater that was stored during two rainy seasons. Korir would let the mosquito larvae swim to the bottom before carefully drinking. And with no hospitals close by, medical emergencies could be especially harrowing— family members and friends experienced many close calls with issues like asthma attacks and allergic reactions to bee stings. Consequently, Korir excelled in first aid training and found himself drawn to medicine in addition to math and science.

Korir has turned his interests into a practical application, turning programmable music box technology into a revolutionary miniature chemistry lab, built with under-resourced communities in mind. Today he is a joint master’s (medicine)/PhD (bioengineering) candidate at Stanford University, where he works with his mentor, Manu Prakash, assistant professor of bioengineering.

“To do this kind of work, you have to have a sense of empathy about the problems of the world. George and I are on the same page,” explains Prakash, who grew up in Rampur, India.

Beyond compassion, Korir brought a solid science education to the task. He attended Kenyan schools, which provided a rigorous education and exposed him to science early. After eighth grade, Kenyan children take an entrance exam to determine who goes on to the national high schools for top students. Korir won admission to Starehe Boys Center in Nairobi. After graduation, he applied to Harvey Mudd on the advice of a friend and at the encouragement of his father. It was at Mudd that Korir says he stumbled upon biomedical engineering, uniting his passion for medicine and engineering.

We are developing diagnostic equipment for regions that have little infrastructure and little capital for buying scientific equipment. Our goal is to equip them to do complex tests.

– GEORGE KORIR ’06

Korir took his Harvey Mudd engineering degree and went to work at a Maryland medical device firm, developing technology for prosthetic limbs. While pursuing a master’s degree in biomedical engineering at Johns Hopkins University, he received a fellowship enabling him to travel to Geneva, Switzerland, where he worked at World Health Organization headquarters developing medical equipment maintenance strategies for developing countries’ resource-planning software. After graduating from Johns Hopkins, he worked at a medical technology startup and a cancer research lab before landing at Stanford. Now his focus is on the development of medical technologies for low-resource settings.

“We are developing diagnostic equipment for regions that have little infrastructure and little capital for buying scientific equipment,” says Korir. “Our goal is to equip them to do complex tests. But the equipment won’t be expensive and won’t require a lot of sophistication to operate. The complexity will be within the equipment.”

The chemistry kit he and Prakash have developed could be used to test drinking water for contaminants, do basic genetic tests, boost farm output or allow children in the poorest schools to delve into science. The target regions are home to those who live on less than $2 a day.

On a recent trip to Kenya, Korir visited hospitals, ideal places for such a device. “They had lots of needs, especially in the area of diagnostics,” he says.

The genesis of the $5 chemistry kit began with a 2010 Christmas party. Prakash received one of the party gifts—a music box—from his wife. He studied it and then created his own music box that operates on paper punch tapes fed into the box with a hand crank. Where holes exist on the tapes, small tines catch, triggering a musical note. Each punch tape can be programmed to code for a different song. One day, as Prakash was playing with the device, he had an aha! moment.

He theorized that the same simple technology could be used for a small chemistry kit. But instead of notes, the holes in the punch tape would generate emissions of a tiny quantity of chemicals needed to run a test. Changing the punch tape could allow the user to run a completely different test. For example, the punch tape might generate the chemicals needed to do an assay, test for a certain disease or check soil to learn what nutrients must be added to grow a crop.

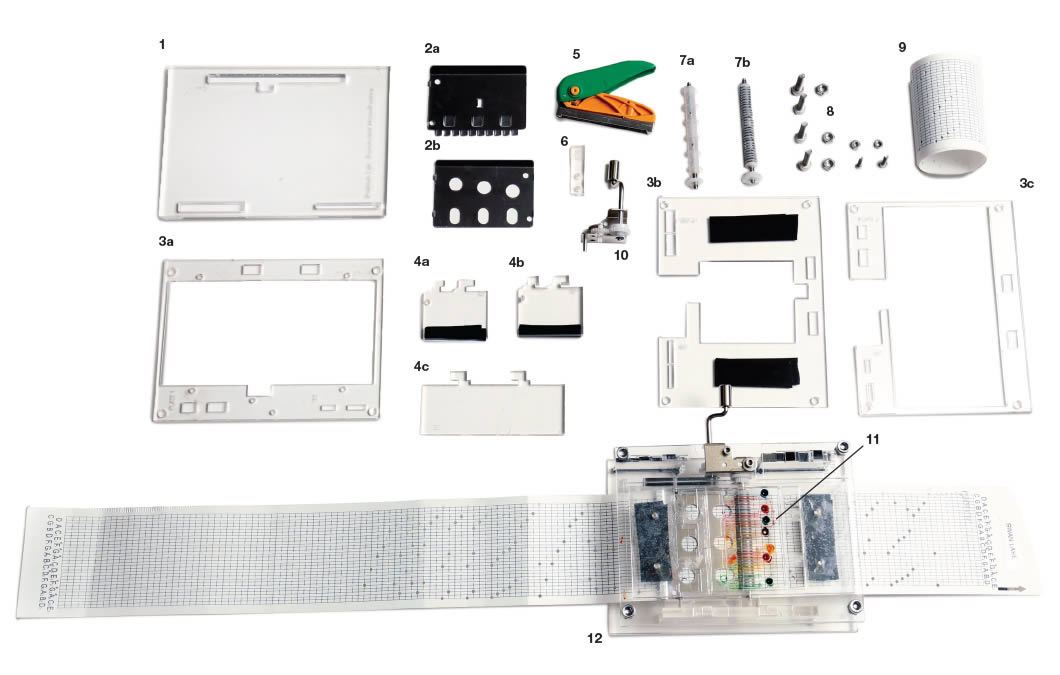

2. Paper guide plates

3. Chip cartridge platform

4. Side plates

5. Paper hole puncher

6. Side gear rods holder

7. Driver rods with gear trains

8. Bolts and nuts

9. Punch card tape

10. Hand crank

11. Microfluidic chip cartridge

12. Completely assembled device

The list of potential applications is limited only by the imagination. “People will come up with uses for the problems they face,” says Korir, who knows all about being resourceful. He spent his childhood building things with his friends, “using whatever materials we could lay our hands on.” Corn stalks and thorns became toy planes. Old milk crates, basketball hoops. Wires and discarded flip flops, fantastic toy cars. He even learned how to sew and knit.

Prakash was familiar with Korir’s extensive academic background and abilities and turned to him to transform the vision into a working product. Korir had worked through some 20 prototypes when Popular Science named the chemistry kit one of 10 brilliant ideas of 2015. The magazine dubbed it “a medical lab in a music box.”

The system has several advantages. It requires no electricity since it operates with a hand crank, and it does not require extensive training to use it. It’s also small enough to fit in a pocket.

To create the kit cheaply, the pair had to think like misers. In the world of extreme poverty, cutting the cost by just a nickel can dramatically widen the circle of people who can afford it, Prakash says. Cost constraints also had a second benefit— they spurred creativity. The chemistry kit joins another invention from Prakash’s lab: the 50-cent microscope. Together, the two devices constitute a basic laboratory for less than the cost of a burger, large fries and a large soft drink. The devices also offer a low-cost introduction to science for children who could not otherwise afford more expensive equipment. “There are kids in America’s rural areas, suburbs and cities who could never afford a fullpriced chemistry set or microscope,” Korir says.

With no more than the chemistry kit and an Internet connection, a child could teach himself to think like a chemist, says Korir. Moreover, the amount of chemicals contained in the kit is so small, there’s no danger of mixing the wrong things and accidentally blowing something up, he says.

Now that the basic device is complete, Prakash plans to send chemistry kits to a few users to see what applications they might develop. Eventually, the kits will be mass-produced for the global market.

“Once you have a community of users, people will really teach themselves a lot,” says Korir. “We envision building an online community of users to share ideas, just like open-source software.”