College News

Copper and Mudd

This is the full transcript of the lecture "Cyprus Mines Corporation and the Career of Harvey Seeley Mudd (1888-1955)" presented at Harvey Mudd College June 18, 2015, by James D. Muhly, distinguished historian, archaeologist and metallurgist. PLUS: Scroll down to view Extra Online Content from Emeritus Professor Mack Gilkeson, who traveled to the Cyprus Mines during the 1970s.

The study of the history and archaeology of ancient Cyprus belongs to that sub-discipline of modern archaeology known as “island archaeology.” Cyprus is the third largest island in the Mediterranean, after Sardinia and Sicily. It is a very mountainous island, with the major ranges being in the western part of the island, the Troodos (highest point 6,403 ft.) and the Kyrenia range along the north coast (highest point 3,357 ft.), also known as the Pendaktylos range. Cyprus has a most unusual geology in that the island was originally formed at the bottom of the sea and, over hundreds of millennia, was literally uplifted from the seabed. In the course of cooling, Cyprus produced remarkably rich copper deposits known as ophiolite deposits. Almost all of this copper is to be found in the Upper Pillow Lavas of the Troodos Mountains.

Unlike the rest of the island, the Troodos have always been blessed with abundant rainfall. In the higher part of the mountains, it rains for five months of the year. This rainfall is the key to the success of the copper smelting industry of Cyprus. Smelting copper ore requires a great deal of wood for fuel. The high rainfall continuously renewed the pine forests of the Troodos which, with careful management, provided a constant source of fuel for the copper industry. Copper ores are basically oxide ores which means that they have to be smelted in a reducing atmosphere, with charcoal, in order to drive off the oxygen and produced metallic copper. Based upon the huge slag heaps that still cover the island, it has been estimated that, over the 3,500 years of its history, the copper industry of Cyprus utilized 60 million tons of charcoal derived from one billion, 200 million cubic meters of pine forest in order to produce 200,000 tons of metallic copper. These figures give you some idea of the extent of the copper industry and why the island has always been regarded as one of the most important sources of copper in the world.

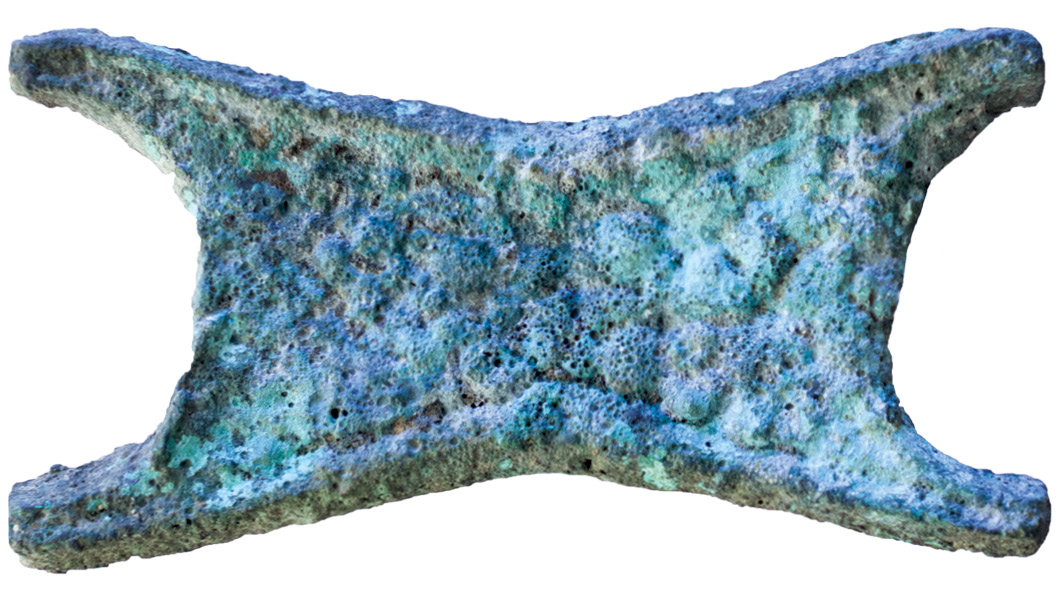

These forests also produced timber for the shipping industry of ancient Cyprus. We tend to forget that Cyprus was one of the great shipbuilding centers of the ancient world. This plays a central role in our understanding of all the problems concerned with the discovery of two Late Bronze Age shipwrecks off the southern coast of Turkey. Both ships went down carrying copper ingots as part of their cargo. From scientific analysis, we now know that all these ingots were made of Cypriot copper and, in shape and size, they are identical to the ingot you have here on display at the College that is also made of Cypriot copper. The first of these shipwrecks to be discovered, known as the Cape Gelidonya ship, seems to have been a merchant’s ship, with a metalworker on board. He had his cargo of copper ingots, tin ingots and metalworking tools. The ship most likely went down in a storm ca. 1200 BCE. The second wreck, the Uluburun ship, represents one of the most magnificent discoveries in the Bronze Age archaeology of the 20th century AD. That ship sank about 1320 BCE and went down with a cargo that included all the luxury and precious goods of the Bronze Age world. These included 10 tons of copper ingots and one ton of tin ingots. Here was a massive shipment of Cypriot copper, most likely destined for the Mycenaean palaces in the Argolid of southern Greece. Although this has been hotly contested over the years, I now believe that both of these ships were Cypriot ships manned by Cypriot sailors and transporting cargoes of Cypriot copper.

So was Cyprus the “Copper Island,” with the name “Cyprus” meaning “copper,” the metal taking its name from the island? This has long been the common belief, but it cannot be correct. By the Early Roman Empire, the 1st century AD, copper had come to be known as aes cyprium, with “cyprium” meaning “of or pertaining to Cyprus,” but the word for copper is Latin aes, aeris. Eventually aes cyprium became simply cyprium and then cuprum so that, by Late Roman times, cuprum had become the Late Latin word for ‘copper’, giving us the modern name for the metal. But the island had been known as Cyprus since the Late Bronze Age, and there is no indication that, before Late Roman times, this name had anything to do with a word for “copper.”

The Bronze Age use of copper was centered, as we have seen, round the production and trade of one particularly object, the copper oxhide ingot. We now know that these peculiar-shaped objects represented the form in which copper was shipped all over the ancient world, especially during the Late Bronze Age, from ancient Babylon in the east to southern France in the west, from Germany in the north to Egypt in the south. The Uluburun shipwreck is a great tribute to the industrial scale of this trade in copper ingots. Almost all of these ingots were produced on the island of Cyprus and were made of Cypriot copper that had been mined and smelted in the great mining district of Skouriotissa, the same mines later acquired by the Cyprus Mines Corporation. Harvey Seeley Mudd came into the possession of one of these ingots, purchased on the antiquities market around 1930, and donated it to Harvey Mudd College. (More on this later.) These ingots have been known since the middle of the 19th century AD. They were first discovered on Sardinia, in the 1850s, and then found on Crete and on Cyprus. Figures from Pharaonic wall paintings, especially from the tomb of the vizier Rekhmire, ca. 1450 BCE, show figures dressed as Keftiu, an Egyptian name for the island of Crete, carrying such ingots and, since the early Italian excavations at the Minoan site of Ayia Triada had produced a hoard of 19 such ingots, they became known as “Cretan ingots” (German Keftiubarren). That designation seemed very unlikely, however, as Crete has no copper deposits.

The modern association of these ingots with Cyprus has come about only through recent archaeological and scientific research. Detailed study of the four stable isotopes of lead, a trace element impurity present in all copper ores, has made it possible to identify the source of the copper used in making these ingots. This research has established that almost all of these ingots, including the one here at the College, were made of Cypriot copper that had been mined in the Skouriotissa area, especially during the years ca. 1400–1200 BCE. Pliny the Elder in his great Natural History, written in the mid-first century AD, (he was killed while observing the eruption of Vesuvius in 79 AD) was not too far wrong when he claimed that Cyprus was the place “where copper was first discovered” (ubi prima aeris inventio).

For the next 2,000 years, following Pliny, we know very little about Cypriot copper. This all changed when, on March 10, 1916, Colonel Seeley Mudd (1861–1926), father of Harvey, along with his financial backers in America, formally created the Cyprus Mines Corporation (CMC) and authorized the sale of 300,000 shares of stock. The purchase price of the land, containing the copper mines around Skouriotissa, was put at $7 million. If you consider the purchase price of the dollar in 1916, you realize that this was an enormous sum of money. Right from the start, the CMC demonstrated a serious commitment to Cyprus and to the copper resources of the island. How did all this come about?

The Mudds were not really miners … They were entrepreneurs, interested in owning mines and financing mining activities.

The first thing to realize is that the entire Mudd family had a serious commitment to mining, not just in copper and not just in Cyprus. Under Colonel Mudd, the family was involved in mining all over the world and not just in copper. Operating mines in California, Colorado, Arizona, Mexico and Peru, and mining not only copper but also silver, gold and lead. This was the basis of the family fortune but, for personal reasons, Colonel Mudd always had a special interest in copper mining and in the possibility of re-opening some of the fabled mines of antiquity, especially those on Cyprus because, according to ancient Greek and Latin literary sources, Cyprus had been the great source of copper from the Greco-Roman world.

The second thing one has to understand is that the Mudds were not really miners. They had no interest in mineral prospection or in the mining and smelting of the ores dug out of the ground. They were entrepreneurs, interested in owning mines and financing mining activities. This brings us to the career of Charles Godfrey Gunther (1880–1929), a little-known figure but one who played a critical role involving the Mudd family in Cyprus. Gunther was a prospector and mineral geologist who had spent his early years in unsuccessful prospecting for mines in the New World. At the same time, the Mudd family had experienced a number of failed exploration efforts in New Mexico, Arizona and Mexico. In frustration Gunther went back to the Brooklyn of his birth. There, from a lifetime of extensive reading, he came across a book by an American missionary, Horatius Bonar: The Desert of Sinai: Notes of a Spring-Journey From Cairo to Beersheba, published in 1857. Here Gunther came upon very convincing descriptions of ancient Egyptian copper mining in the Sinai. Gunther concluded, based upon additional reading regarding Turkey and Cyprus, that he had been working in the wrong part of the world. Forget the New World; the Old World held what he was looking for. Gunther was very persuasive; he managed to persuade Colonel Mudd and his financial backers to finance his prospective travels in the Sinai, the Levant and in Cyprus. On Sept. 12, 1912 they gave Gunther a $5,000 letter of credit (as things were financed before credit cards and international internet transfers) and off he went to Cairo . Explorations in the Sinai and the Levant were not successful and, on Dec. 26, 1912, Gunther set sail from Port Said, Egypt, to Famagusta in Cyprus. Here Gunther found exactly what he had been looking for, and his report on work in Cyprus, especially in the mining complexes at Skouriotissa in the Troodos mountains, convinced his backers to establish the CMC in 1916. My reason for giving this very abbreviated account rests in my firm conviction that, if Gunther had not read the book by Bonar in the Brooklyn public library, the CMC would never have come into existence, and we would not be here today. I am a firm believer in serendipity and in the fate that awaits every one of us.

One factor of ancient mining needs to be explained. To dig deep underground is to go below the existing water table. The mineshaft fills with water and only by getting rid of that water could mining activity continue. At Skouriotissa Gunther discovered outside the openings of two ancient mines, known as skopes or audits, huge heaps of broken pottery. The dump covered an acre of ground and was nearly 20 feet deep. Gunther knew right away that these were the broken fragments of the jars that had been used to carry water out of the ancient mine. He reasoned: with such primitive technology the ancient miners could not have gone very deep underground. Therefore much has to remain to be exploited by modern technology. On the basis of such reasoning, Colonel Mudd and his investors were willing to invest $7 million. They had approached J. Pierpont Morgan for financial help on what they admitted was a gamble. His terse reply was: “I never gamble.”

In 1916, with the establishment of the CMC, Harvey Seeley Mudd, eldest son of Colonel Seeley Mudd, decided it was time for him to take an active interest in Cyprus and the CMC. His concerns, up to this point, had been with the family’s mining interests in the New World. Now Harvey Mudd realized that he needed to take active control of what was being run by Gunther. This was a very difficult period for everyone. The First World War had reached truly savage conditions and, with the collapsing Ottoman Empire now fighting on the Axis side, it had engulfed the entire world, all the way to Australia and New Zealand. Cyprus had become part of the British Mandate in 1878 but, on Oct. 21, 1915, Lloyd George, the British PM, had offered Cyprus to Greece if the Greeks agreed to join the Allied powers in the Great War. Greece refused the offer, but this was just one of many reasons why Harvey Mudd realized that Cyprus now demanded his serious attention. On June 27, 1919, Harvey Mudd arrived in Cyprus on his first visit to the island. He was met in Nicosia by Gunther, and the two of them went off to Skouriotissa.

We now have to face a remarkable situation. What was actually being mined in 20th century Cyprus was not copper ore but iron pyrites. The main ore deposits of Cyprus had always been iron and sulphur, with small amounts of copper. The copper, it turned out, had all been mined away by the ancient miners. What was left was iron and sulphur. The iron was of little use because it contained too much sulphur to be turned into usable iron. The sulphur itself, however, was extremely valuable. It was used in insecticides, fertilizers and in many sulphide medications. More important was its use in making sulphuric acid that, in the early 20th century, was used in the production of paper, textiles, beer, film, plastics, munitions, rubber and even matches. Cyprus became one of the major suppliers of sulphur-rich pyrites to the western world, along with Rio Tinto in Spain (in which the Mudd family also had interests).

Harvey Mudd was probably the most progressive employer in America in the first half of the 20th century. In the years from 1930 on, life in Cyprus greatly improved, thanks to Harvey Mudd. The CMC built a hospital, a golf course, and ran summer camps for children. The CMC tackled the great plague of malaria, a major health problem in Cyprus for thousands of years. They drained the marshes and planted large numbers of eucalyptus trees to soak up the water. In the years after World War II the CMC became a major force for social and health care services in Cyprus. By 1948–1949, when the Cyprus government finally decided to do something about malaria, the health authorities immediately turned to the CMC. By this time, the company had renovated its hospital, making it the most modern facility in the Near East, and they were operating seven medical clinics on the island. For its own workers, the CMC established a pension plan and offered its employees medical insurance. Harvey Seeley Mudd was truly a most remarkable man. He said that, when the mines were finally exhausted, and mining operations came to an end, he felt a moral obligation to leave Cyprus a better place than it had been when everything started back in 1916.

Harvey Mudd had long been interested in education in the Claremont area and served as a trustee on the board of Claremont College. He also had a passion for classical music and was instrumental in the establishment of the Los Angeles Philharmonic. In the early 1950s, Harvey Mudd became convinced that what the Claremont area needed was a small technical college of science and engineering. There was general agreement that this new college would best serve society by staying small and insisting on high standards rather than by straining its resources in reaching for quantity. The feeling was that “The graduates it produced should not be just good scientists and engineers but men capable of assuming the increasing social, civic, and business responsibilities imposed on management by modern technology” (D. Lavender, p. 314). On Monday, April 11, 1955, Harvey Mudd met with the board of Claremont College to discuss plans for this new college. The next day, he died of a heart attack. On Nov. 12, 1955, the Claremont College Board of Fellows unanimously recommended the establishment of a college of science and engineering to be named Harvey Mudd College, in memory of Harvey Seeley Mudd. Formal action on this recommendation was taken on Dec. 14, 1955 and, on April 10, 1957, they laid the cornerstone of the first building, a residence hall for 88 men.

James D. Muhly held an emeritus professorship at the University of Pennsylvania and served a term as director of the American School of Classical Studies at Athens. He received the Archaeological Institute of America’s Pomerance Award for Scientific Contributions to Archaeology.

Extra Online Content

A Visit to the Cyprus Mines

As shared by Mack Gilkeson, professor of engineering emeritus

Over the decades, I’ve sought to extend travels to include whatever was within reach. So not surprisingly, in 1973 when I gave a paper at a Tel Aviv conference, I chose to include the Cyprus Mines in my itinerary. Along the way, I also managed Istanbul and Tehran (talks on Clinic), Moscow and London.

Early on, maybe 1963, I had read David Lavender’s somewhat overly romantic book on The Story of Cyprus Mines. I was quite enchanted by the book, which I identified as closely related to Harvey Mudd College origins. Parenthetically, Lavender’s son, also a David, was a member of the HMC development team in the early days and a friend of mine.

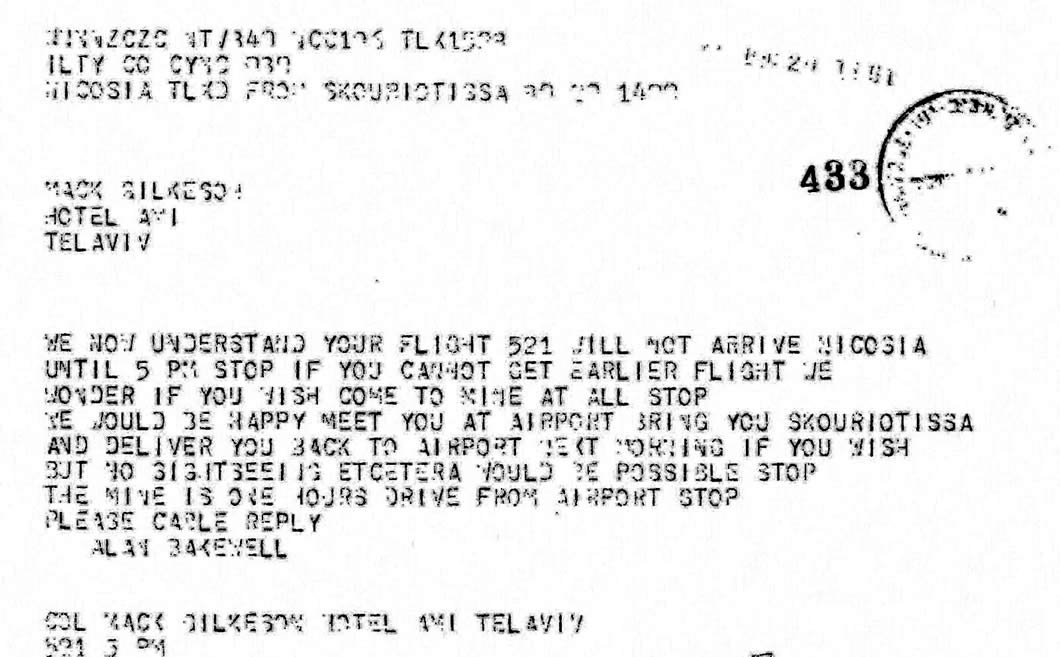

So, planning my itinerary, I obtained permission to visit the mines, probably through Joe Platt. And off to Israel, Cyprus and the rest in late December 1973. No direct flights from Tel Aviv to Nicosia. Hence, after the conference, I flew to Ankara overnight and reached the Nicosia airport by late afternoon the next day. I was met by a mines official, driven to the mines, given a late supper, entertained and went to bed in their guest quarters.

The visit included a wonderful tour the of mines, a dozen snapshots, including my favorite, of the cave entrance to the original mine, developed first by the Phoenicians, and then, with newer technology, again by the Romans. To top it off, that night I got to help decorate the huge Cyprus Mines Christmas tree.